Precision Injection Molds & Molding Solutions from China

End-to-end manufacturing partner for complex injection molds and plastic parts. From DFM analysis to mass production — we deliver engineering excellence with transparent communication.

Complete Manufacturing Capabilities

From prototype to mass production, we provide integrated mold making and injection molding services under one roof.

Injection Mold Manufacturing

Precision molds with tolerances up to ±0.02mm for complex geometries and multi-cavity designs.

Hot Runner Systems

Zero-waste hot runner molds that reduce cycle times and ensure consistent part quality.

Overmolding & Insert Molding

Multi-material bonding solutions for soft-touch surfaces and metal-plastic integration.

2K / Two-Shot Molding

Dual-material injection for complex assemblies with reduced secondary operations.

Gas-Assisted Molding

Hollow structural parts with superior strength-to-weight ratio and reduced sink marks.

Need a complete solution? We handle everything from mold design to volume production.

Discuss Your ProjectProblems We Solve

Working with overseas suppliers can be challenging. Here's how KTM addresses the most common pain points in mold sourcing.

Common Pain Points

Communication Barriers

Repeated explanations, misunderstood specs, and delayed responses causing project confusion.

Quality Inconsistency

Molds that don't match drawings, dimensional deviations, and unreliable part quality.

Hidden Costs

Unexpected price increases after project starts, unclear quotation breakdowns.

Incomplete Documentation

Missing reports, no traceability, difficult to verify quality standards.

The KTM Solution

Seamless Communication

English-speaking engineers who understand technical requirements. Direct communication with no middlemen.

Engineering-First Approach

DFM analysis and Moldflow simulation before production to prevent issues proactively.

Transparent Pricing

Detailed quotation with full cost breakdown. No surprises, no hidden fees.

Complete Documentation

Full reports: DFM, trial reports, dimensional inspection, material certificates — all delivered.

Tired of unreliable suppliers? Experience the KTM difference with your next project.

Request Free ConsultationOur Project Process

A structured, transparent workflow that keeps you informed at every stage — from initial inquiry to final delivery.

Inquiry & Review

Submit your 3D files and requirements. Our engineers review and respond within 24 hours.

DFM & Quotation

Receive detailed DFM analysis, Moldflow report, and transparent pricing with full breakdown.

Mold Design & Build

3D mold design approval, precision machining, and weekly progress updates with photos.

Trial & Validation

T1 sampling, detailed trial report, dimensional inspection, and optimization if needed.

Delivery & Support

Safe packaging, reliable shipping, and ongoing technical support for production.

Ready to get started? Let's discuss your project timeline and requirements.

Start Your ProjectCase Highlights

Real projects, real results. See how we've helped manufacturers across industries solve complex molding challenges.

Dashboard Air Vent Assembly

Complex overmolding with tight assembly tolerances. Previous supplier failed to achieve consistent soft-touch bonding.

Hot runner mold with optimized gate design. Moldflow simulation ensured proper TPE flow and bonding adhesion.

Smart Device Enclosure

High-gloss Class A surface with zero visible defects. Ultra-thin walls requiring precise filling balance.

Valve gate hot runner system with sequential filling. Mirror-polished cavity with specialized venting design.

Pipe Fitting System Components

Multiple complex thread forms with tight dimensional tolerances. Required 1M+ shot mold life guarantee.

High-hardness H13 steel with precision thread inserts. Unscrewing mechanism with servo-motor control for thread integrity.

Have a similar project? Let's discuss how we can help achieve your goals.

Share Your Project DetailsApplications Across Industries

From automotive to aerospace, we deliver precision molds and parts tailored to your industry's specific requirements and quality standards.

Automotive

Interior, exterior, under-hood components with IATF 16949 aligned processes.

Learn MoreAerospace

High-precision components meeting strict aerospace material and tolerance requirements.

Learn MoreConsumer Electronics

High-gloss housings, precision connectors, and thin-wall enclosures for devices.

Learn MoreIndustrial Equipment

Pipe fittings, valves, machinery components with long-term durability requirements.

Learn MoreMedical Devices

Clean-room compatible molds for medical-grade components with full traceability.

Learn MoreHome Appliances

Durable housings, functional components, and aesthetic parts for household products.

Learn MoreDon't see your industry? We work with diverse sectors — contact us to discuss your specific application.

Discuss Your ApplicationWhy Partner With KTM?

We're not just another mold supplier — we're your manufacturing partner committed to delivering engineering excellence and transparent collaboration.

Direct Factory Access

Work directly with our 80+ person facility — no trading companies, no middlemen. You get factory pricing and direct communication with the team building your molds.

Dedicated Engineering Team

Our engineers provide DFM analysis, Moldflow simulation, and design optimization — catching issues before they become costly problems in production.

Proven Export Experience

Successfully exported to USA, Germany, UK, France, Mexico and 20+ countries. We understand international quality standards and documentation requirements.

Transparent Project Management

Weekly progress updates, clear timelines, and honest communication. You'll always know exactly where your project stands — no surprises, no excuses.

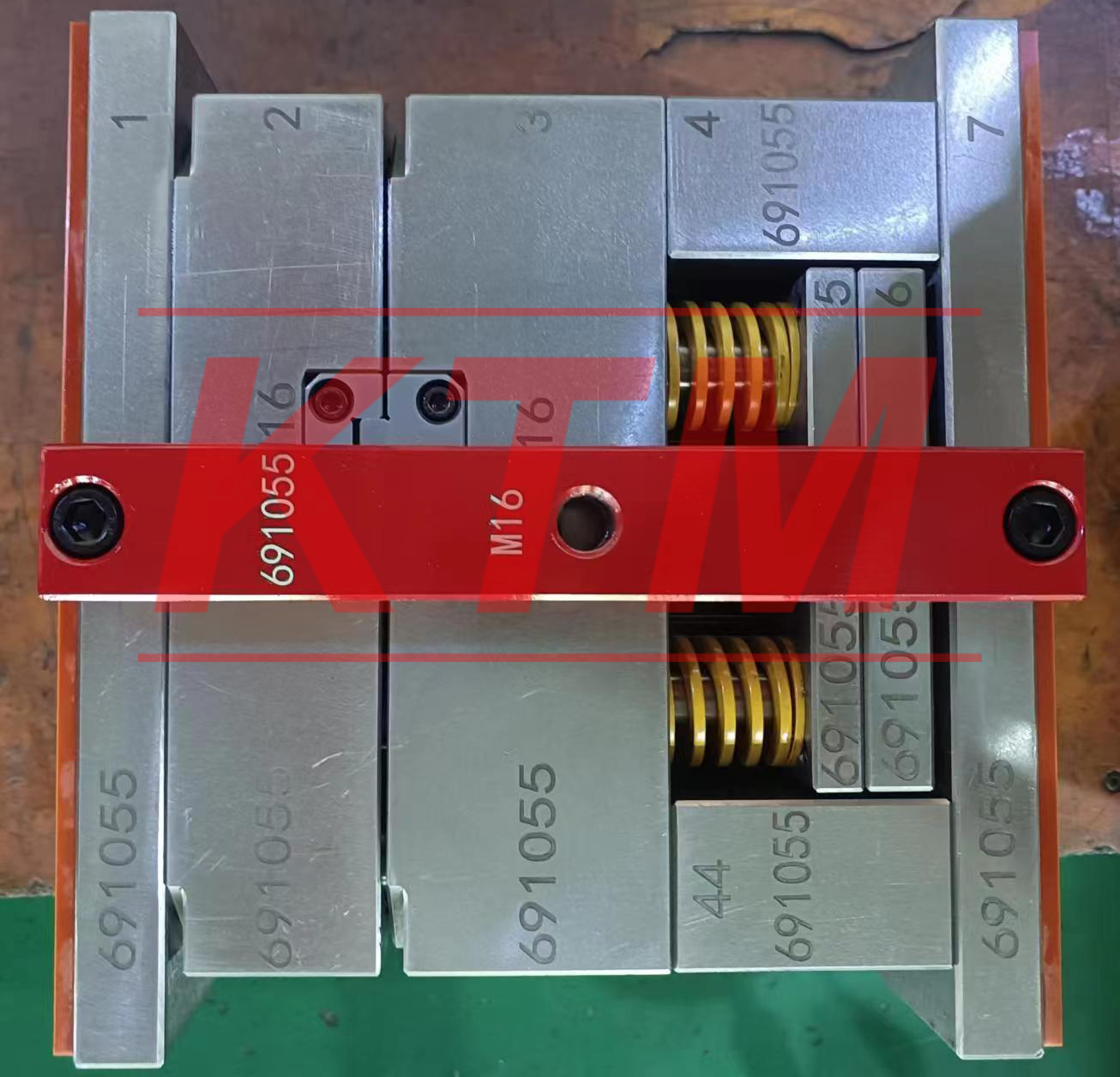

Workshop & Manufacturing

Take a look inside our facility — modern equipment, organized workspace, and a team dedicated to precision manufacturing.

Want to see more? Schedule a virtual factory tour with our team.

Schedule Factory TourQuality Control & Export Standards

Rigorous quality systems aligned with international standards ensure every mold and part meets your specifications.

Incoming Material Inspection

Every steel block verified with material certificates and hardness testing before machining begins.

In-Process Inspection

Critical dimensions checked at each manufacturing stage with documented measurement records.

CMM Dimensional Report

Full 3D coordinate measuring machine inspection with detailed dimensional analysis reports.

Final Mold Validation

Complete trial run with detailed T1 sample report, parameter documentation, and part approval.

Quality is non-negotiable. Request our quality manual and certification documents.

Request Quality DocumentationTrusted by Manufacturers Worldwide

Join the growing list of companies who trust KTM for their precision mold and molding needs.

"KTM's engineering team identified potential issues during DFM review that would have cost us significant time and money. Their proactive approach and clear communication made them feel like an extension of our own team."

"The documentation quality from KTM is exceptional. Complete DFM reports, detailed trial documentation, full dimensional data — exactly what we need for our quality records. Professional service from start to finish."

Ready to join our satisfied clients? Let's discuss how we can support your project.

Start a ConversationReliable Injection Mold & Plastic Injection Molding Manufacturer in China

KTM is a professional injection mold and plastic injection molding manufacturer based in China. We help global customers design, build, and produce high-quality plastic parts with stable quality and reliable delivery.

As a direct factory with in-house engineering, tooling, and molding capabilities, we support projects from prototype tooling to high-volume production.

A Factory-Focused Manufacturer, Not a Trading Company

KTM is not a trading company or a sourcing platform. We are a factory-focused manufacturer specializing in injection mold manufacturing and plastic injection molding.

With an experienced engineering team and a complete production system, we focus on solving tooling and production challenges for B2B customers worldwide.

Direct Manufacturing

Own factory with complete production capabilities

Experienced Team

Skilled engineers solving complex challenges

B2B Focused

Dedicated to serving global business customers

Want to know more about our capabilities? Let's start a conversation.

Learn More About UsPrecision Injection Molds & Plastic Parts Manufacturing

We manufacture precision injection molds and plastic injection molded parts for various industries. Our comprehensive capabilities cover the entire production spectrum.

Hot Runner Molds

Advanced hot runner systems that eliminate material waste, reduce cycle times, and ensure consistent part quality for high-volume production.

Overmolding & Insert Molding

Multi-material bonding solutions combining different materials or integrating metal components for enhanced functionality and durability.

2K & Multi-Shot Molding

Dual-material and multi-shot injection capabilities for complex assemblies requiring different materials in a single molding cycle.

Gas-Assisted Molding

Hollow structural parts with superior strength-to-weight ratios, reduced sink marks, and improved surface quality for large components.

Prototype to Mass Production

Complete project lifecycle support from initial prototype tooling through low-volume runs to full-scale mass production manufacturing.

Industries We Serve

Have a project in mind? Let us show you how our capabilities can meet your requirements.

Discuss Your ProjectEngineering-Driven Manufacturing

At KTM, every project starts with engineering analysis. We believe that thorough upfront planning prevents problems and ensures successful outcomes.

Before Mold Manufacturing

- DFM Analysis to optimize part and mold design

- Moldflow Analysis to reduce molding risks

- Clear Planning for tooling structure and production

During Tooling & Production

- Detailed Trial Reports with process parameters

- Dimensional Inspection reports with full data

- Material Certifications for traceability

This engineering-first approach helps customers reduce risk, avoid rework, and achieve stable production — saving time and cost in the long run.

Experience our engineering-driven process. Start with a free DFM analysis for your project.

Get Free DFM AnalysisYour Reliable Manufacturing Partner

We focus on long-term cooperation, not one-time orders. Here's what sets us apart from other suppliers.

Direct Factory

Work directly with our production facility. No middlemen, no mark-ups — just transparent factory-direct pricing and communication.

Experienced Team

Our engineering and tooling specialists bring years of experience solving complex manufacturing challenges for global customers.

Clear Communication

English-speaking engineers who understand technical requirements. No translation delays or miscommunication issues.

Transparent Management

Weekly progress updates, clear project timelines, and honest reporting. You always know exactly where your project stands.

Stable Quality

Consistent quality through rigorous inspection processes and complete documentation for every project we deliver.

Competitive Pricing

Best cost-performance ratio with transparent quotations. Quality manufacturing at fair prices without hidden fees.

Ready to experience the KTM difference? Let's discuss how we can support your manufacturing needs.

Start a ConversationFrequently Asked Questions

Get answers to the most common questions about working with KTM for your injection mold and molding projects.

Lead time varies based on mold complexity. Simple molds typically take 3-4 weeks, standard production molds 4-6 weeks, and complex multi-cavity or hot runner molds 6-8 weeks. We provide a detailed timeline during the quotation phase and keep you updated throughout the project.

Yes, comprehensive DFM (Design for Manufacturability) analysis is included with every project. Our engineering team reviews your part design, identifies potential issues, and provides recommendations for optimization. This helps prevent problems before mold fabrication begins, saving time and cost.

We accept most standard 3D CAD formats including STEP (.stp), IGES (.igs), SolidWorks (.sldprt), Pro/E (.prt), and Parasolid (.x_t). 2D drawings in PDF or DWG format are helpful for specifying tolerances and requirements. If you have a different format, contact us and we'll find a solution.

We manufacture a full range of injection molds including: standard injection molds, hot runner molds (valve gate and open gate), overmolding/2-shot molds, insert molding molds, 2K/two-color molds, gas-assisted injection molds, and unscrewing molds for threaded parts. Our team can advise on the best solution for your application.

Yes, we provide complete injection molding production services from prototype runs to high-volume mass production. Our facility includes injection molding machines ranging from 50 to 1500 tons, capable of handling various materials and part sizes. We can also handle secondary operations like assembly, printing, and packaging.

Quality is assured through our ISO 9001 certified processes: incoming material inspection with certificates, in-process checks at each stage, CMM dimensional inspection, and comprehensive trial reports. All documentation including DFM reports, trial reports, dimensional data, and material certificates are provided. We support PPAP documentation for automotive customers.

We have successfully exported molds and parts to over 20 countries including USA, Germany, UK, France, Italy, Spain, Mexico, Costa Rica, and throughout Europe. Our team is experienced with international shipping, customs documentation, and the specific requirements of different markets.

Both options are available. We can work directly from your finalized 3D designs, or our engineering team can assist with design optimization for manufacturability. If you have a concept but need help developing it for injection molding, we can provide design support and recommendations based on our manufacturing expertise.

Have more questions? Our team is ready to help with any specific inquiries about your project.

Ask Your Question